Screen Printing

Water Based Screen Printing

Water-based screen printing ink is typically a better option when printing on fashion blanks because the hand (feel) of the ink is so much softer. If done right, you should not be able to feel the ink on the garment once it’s been washed.

Water-based ink by itself does not have a high opacity (coverage) due to the viscosity (thickness) of the ink. It is truly liquid form with low density making the colors very dull when printed directly on on dark garments.

In order to use this ink on dark shirts, you need to screen print a white base or add a discharge agent to the ink. The discharge agent creates a chemical reaction. Once heated to the proper temperature, it actually pulls the dye from the fabric and integrates the new ink pigment. This allows for nice bright coverage.

Plastisol Screen Printing

Plastisol ink is one of the most commonly used screen printing ink type and has been around for decades. It has been the primary ink until fairly recently as more and more companies have been converting. Plastisol is a much more user friendly ink, as it is more accurate for matching Pantone colors. It does not have a shelf life so you can mix extra ink for the job to use at a later time.

The viscosity of plastisol ink is much thicker making for a more opaque print. Making the coverage much better, especially on dark garments.

Since there’s no fabric dying involved in the printing process, plastisol can be used for most fabric types. The ingredients of the shirt do not have much effect on the outcome of colors. This is a preferred process from a production standpoint, as it is a standardized ink that works across a multitude of different garment substrates.

The downside is that the ink has a much thicker feel to it. Since it is sitting on top of the fibers versus soaking into them, it is a noticeable hand and can often feel similar to rubber or plastic if not based down..

Discharge Screen Printing

Discharge ink is a water based formula that allows printing on dark fabric without the need of additional ink layers. In the past, when printing on dark fabrics, manufacturers often had to add a layer of ink in order to make sure that the print is visible and accurate. This resulted in a less desirable hand-feel. Thanks to discharge ink, the additional layer is no longer needed and instead, the printing process actually deactivates the color of the fabric itself and replaces it with the chosen print colors. The result is a thin, single layer of ink that is both visibly clear and feels pleasant to the touch.

Discharge ink is able to do so thanks to a dedicated deactivating chemical, which essentially bleaches the fabric and works particularly well on fabrics dyed using reactive ink. Unlike bleach, however, discharge ink does not harm the fabric at all.

Metallic Screen Printing

Metallic Screen Printing Inks are a product that allows you to get the look of metal without the hassle. The pigments are made of traditional metals to create a range of popular hues such as ranges of gold and silver. These costly metals are replaced with more affordable and durable metals like copper, zinc and aluminum to create the desired look. Balancing copper and zinc provides different variations of gold metallic ink while aluminum is the base for silver hues. Metallic ink printing combines small particles of copper, zinc, and aluminum to a clear plastisol ink to print the desired design onto your choice of fabric or solid paper material.

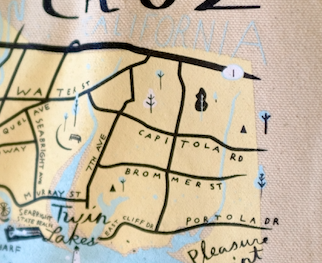

They're ideal for printing on dark garments, as the metallic effect really pops. Here at West Cliff Ink, we use primarily Gold and Silver metallic inks.

Heat Transfer

With heat transfer, also known as digital transfer, your custom logo or design is printed onto transfer paper and then ink is thermally transferred from the paper to your fabric using heat and pressure.

Heat transfer can be performed in a few different ways. Here at West Cliff Ink we do digital water based transfers and screen printed plastisol heat transfers. The water based heat transfer will feel closer to the fabric, whereas the screen printed plastisol heat transfer will feel “puffier” (great for sports jerseys).

Heat-transfer printing is more useful for some printing situations than others. When applied correctly, heat-transfer printing produces high-quality, colorful prints of photo-realistic images, which makes it useful for digital photography prints. Heat-transfer printing works well for adding or customizing prints on fabrics such as athletic uniform numbers. Because heat-transfer prints are durable, they work well when the printed object is exposed to the elements. Heat-transfer printing is a better long-term solution than using direct-thermal printing, which is known to wear out.